Factory audit & Third party quality control: Factory audit & Third party quality control:

Quality standard

Method of acceptance sampling

This proven method is widely used to decide whether or not to accept or reject a production lot without checking every single item of the lot. Performed on randomly-selected sample items, once the production lot has been completed and packed, this standard is recognized by every industrial company.

Acceptance sampling is not an alternative to process improvement. Instead it should complement improvement efforts by providing incentives. It also serves as a temporary measure for ensuring quality until successful improvements are made.

Alternatives

There are five possible alternatives to acceptance sampling:

Release all lots without any Production Inspection, Release all lots without any Production Inspection,

Discard all lots without any Production Inspection, Discard all lots without any Production Inspection,

100% Production Inspection of all lots, 100% Production Inspection of all lots,

Accept sample, reject discarded lots, Accept sample, reject discarded lots,

Accept sample with 100% Production Inspection of rejected lots. Accept sample with 100% Production Inspection of rejected lots.

Focus on Acceptable Quality Levels

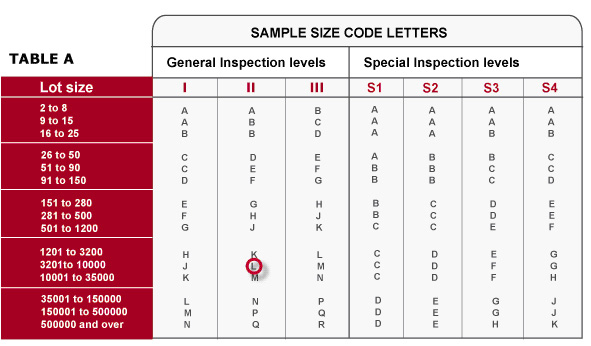

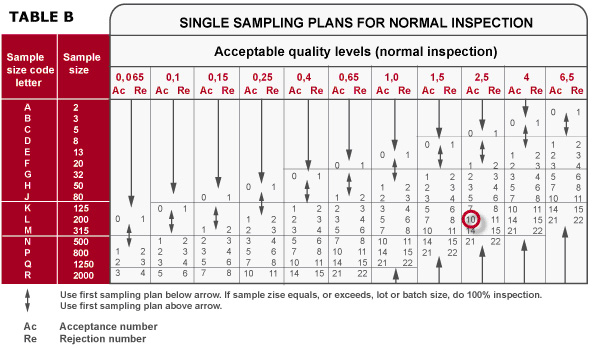

SET Quality Inspectors throughout China use the ISO 2859 tables (also known as AQL tables) to measure acceptable levels of quality of the Chinese products they inspect. These tables are a US standard with equivalents in all national and international standardization organizations (ANSI/ASQC Z1.4, ISO 2859, NF06-022, BS 6001, DIN 40080).

How do I determine the right sample size and acceptance number?

For a hypothetical inspection of a 4,000-unit lot, with an Acceptable Quality Level of II, Table B indicates that the sampling size should be 200 units. For an AQL of 2.5, the corresponding acceptance number is 10.

|